IPL High-Intensity Ion Exchange Membrane

Key words:

IPL High-Intensity Ion Exchange Membrane

Characteristics of IPL main component products

Product name: Ionic interlayer, Ionoplast Interlayer, referred to as IPL

Composition: Ethylene and methyl methacrylate ionic copolymer

Overview: The Zhi Cheng IPL high-strength ionic interlayer is made from ethylene and methyl methacrylate ionic copolymer mixed with various additives. Its laminated glass has high transparency, high mechanical strength, good impact resistance, and can withstand hurricane and typhoon levels. IPL ionic interlayer laminated glass is currently the safest glass in the country.

Features

Hardness is 100 times that of traditional PVB materials;

Tear resistance is 5 times that of traditional PVB materials;

Yellowing index is less than 1.5;

UV filtering, natural weathering test without defects;

High edge stability, good compatibility with structural adhesives; high-strength bonding capability with metals.

Recommended application range

Buildings with full glass structures that require high impact resistance and load-bearing capacity, such as: glass floors, glass walkways, aquariums;

Places with high safety factor requirements, such as: sports venues, squares, commercial centers;

Solar curtain walls, super high-rise buildings, large public curtain wall safety glass, and buildings that are resistant to hail, hurricanes, and typhoons;

Extra-large architectural glass and large-span skylights, as well as security applications in jewelry display cabinets, bank counters, etc.

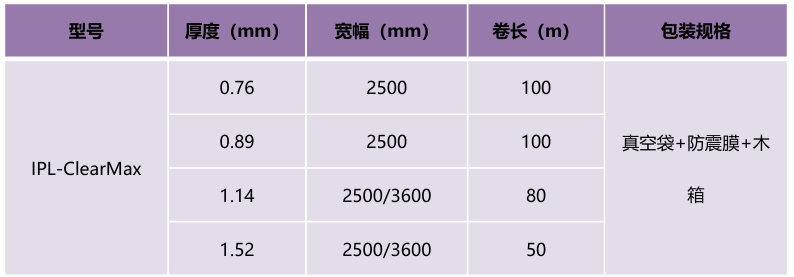

Product specifications

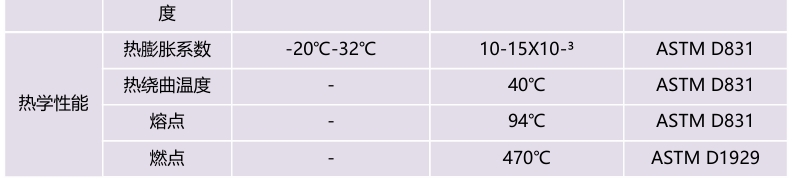

Product performance parameters

Storage and transportation

- Temperature below 25 degrees Celsius, humidity below 30%;

- Avoid direct sunlight, waterproof and moisture-proof, keep away from heat sources, do not squeeze;

- Unused film should be properly stored in vacuum; it is recommended to make a sample of at least 0.5㎡ of glass before the next use to confirm product quality;

- IPL high-strength ionic interlayer material should be stored in rolls inside vacuum moisture-proof bags. IPL interlayer materials supplied in roll form can be stored at room temperature, but should be used as soon as possible after opening the vacuum moisture-proof bag. Unused products should be sealed and stored in a constant temperature and humidity room.

- It is recommended to use the purchased interlayer within two years from the date of purchase to avoid performance degradation as much as possible.

Online feedback

* Note: Please make sure the information is filled in accurately and keep communication smooth. We will contact you as soon as possible.